KIRBBRIK partners with a large-scale international manufacturer with extensive technical infrastructure and engineering depth. Our facility features automated batching, forming, firing and machining lines, as well as in-house laboratories and strict QA systems .

Advanced control of firing, chemistry and dimensional precision, far exceeding typical construction brick requirements.

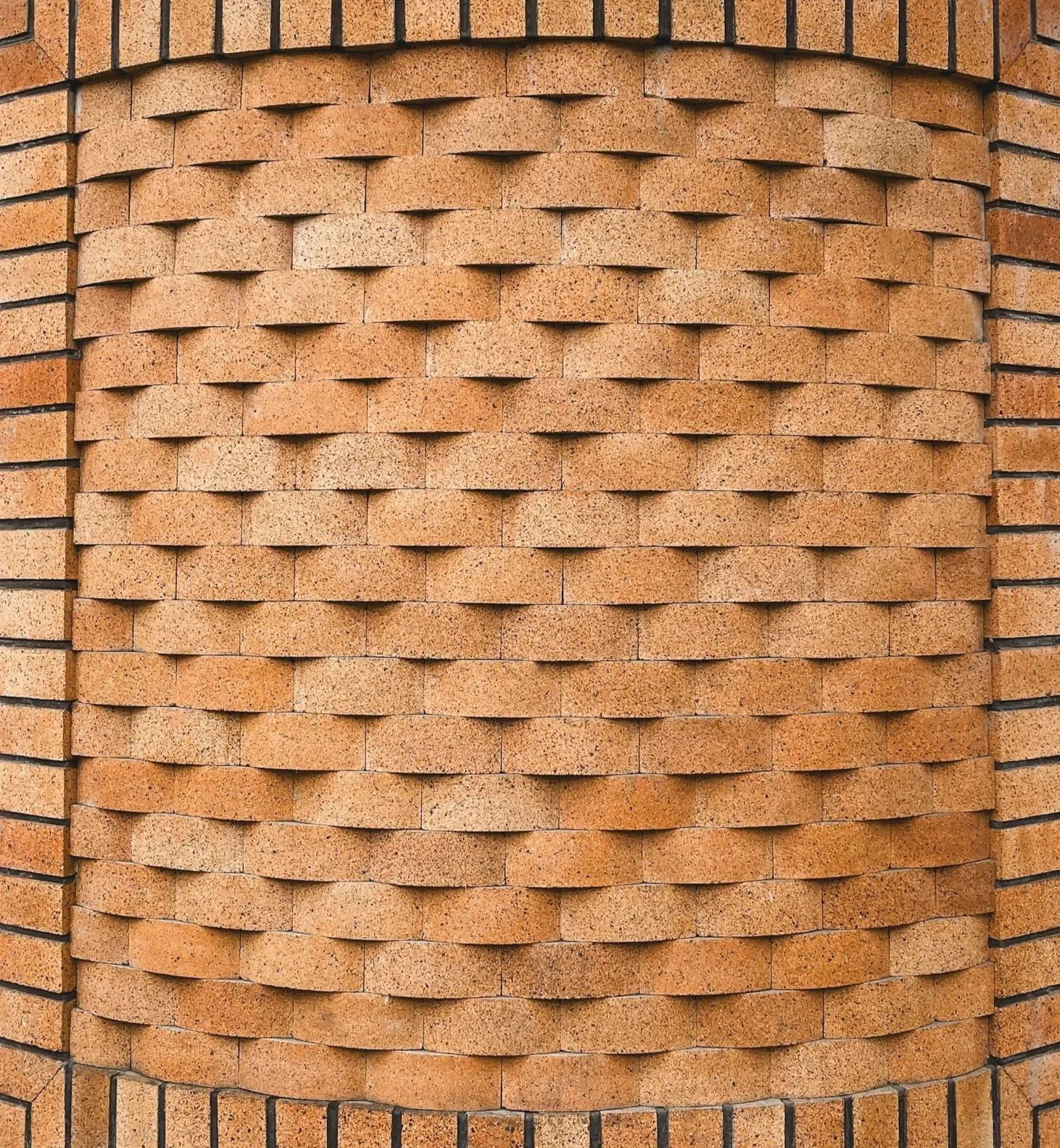

Tight tolerance and consistency suited to clean architectural lines and predictable coverage.

Full QA testing, including compressive strength, absorption and thermal performance.

Capability for non-standard shapes and special formats, including corner units, soffit bricks, slips and custom colours/textures.

Experienced global logistics + documentation support for heavy ceramic products.